Since every colour needs its stencil, the final costs may be larger for the set-up value. Once the screens are made you can print as many t-shirts you like utilizing cheap tools, making it extremely cost-effective for big orders. Cost per shirt drops with an rising number of orders. Single piece orders could be processed economically utilizing this expertise. Hence customers can print their designs using custom t-shirt designing tools like ImprintNext without having to bother ordering ten pieces of the identical mannequin.

You don't want additional house to retailer your printed inventory either, as it could be instantly shipped. DTG printing does offer bulk discounts, but when the order measurement is just too large, the printing will take enough time. If you give you a very elaborate t-shirt design with lots of colors, DTG is the method in which to go. Photorealistic images and detailed designs is the place this system thrives greatest.

So so as to reduce the carbon footprint of your business setup, it's pivotal to solely take orders that can be managed by your setup. In 1960 a person by the name of Michael Vasilantone developed a rotary multicolor garment display screen printing machine.

Someone who will stand behind what they sell, and someone who takes the time to test what they promote. After all, Your funding is virtually nugatory in case your supplier disappears and also you want assist. Even then, 2nd hand, it is worth will plummet should you ever decided to sell it if the " manufacturer" just disappears. You need somebody that may still be here as soon as the " craze" has gone.

Screen printing works finest with commonplace stable designs that are much less advanced. Screen printing is senseless to use in case you are looking to print just some t-shirts. The cost of organising display printing and designing the stencils is merely too excessive. This is why display screen printing is primarily employed when printing t-shirts in bulk. Otherwise, it’s not cost-effective and takes too lengthy to be arrange. Screen Printing – It is cost-effective for bigger batches but not much for one-offs. Preparing stencils for the projects means it has a excessive setup cost, making it inefficient for small orders.

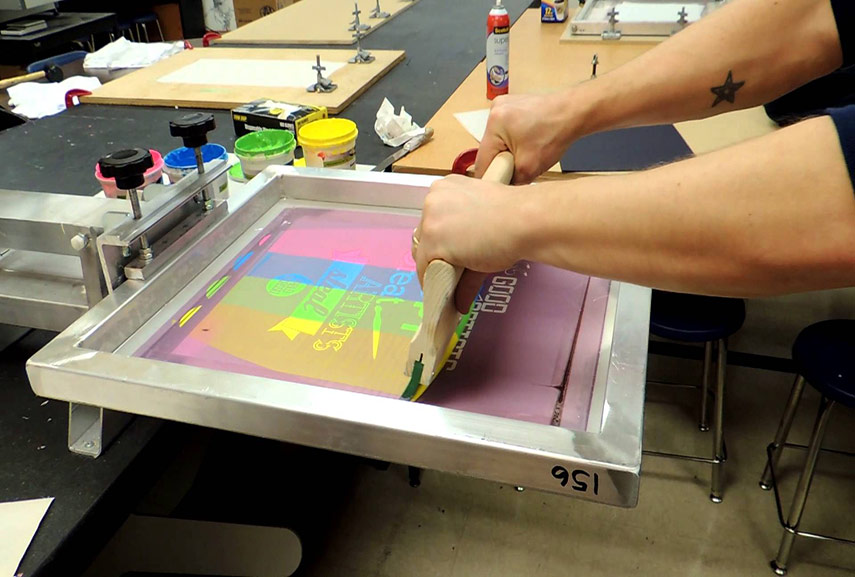

Screen printing is most cost-effective for larger batches of shirts. The stencil course of means that set-up prices are somewhat larger, but it additionally makes screen printing extra environment friendly for large orders of 1 design. This means that certain types of t-shirt designs are better suited to every method. Next, a woven display stencil is used to apply a single colour of ink at a time — one stencil per color used in the shirt’s design. If you’re seeking to design and print your own custom t-shirts, you’ve likely encountered these two terms — DTG printing and display printing. Now you’ve read some extra about every methodology of t-shirt printing; you can see how different they're.

DTG comes out swinging in the second spherical with wonderful color mixing. It’s the ability to create clean gradients and a range of colors by blending a lesser quantity of colors.

People try to get away from the thick, heavy, vulnerable to peeling facet of issues. I constantly get contacted about how superior it's that I don't use vinyl, and have really gotten fairly a bit of enterprise from word of mouth over it. Digital DTG printing machine printing has no restrictions on the variety of colors. No want for colour registration, gradient colors can obtain photo-level results. To make the most effective decision for your business, understanding all these technical variations between the 2 customized attire printing methods is important.

The equipment used in display screen printing are fairly bulky and need lots of house – most definitely not a back-office affair. The vinyl can be utilized to all kinds of cloth – cotton, polyester, nylon, and so forth. It’s quite time consuming – it takes plenty of time to chop out the vinyl and weed it out.

Although we can print up to 12+ colours per shirt, this won’t be economical except you’re printing giant portions. Therefore, try to keep within 5-6 colors as an excellent guideline. Direct To Garment is like your printer in your house or workplace.

By boosting the number of available color selections from nine to virtually unlimited, with DTG printing, you presumably can take pleasure in photo-realistic renditions of designs. Other Asian countries adapted the strategies to their own material coloring and modified the technique. Japan experimented with paper minimize out stencils to create imagery that could then be transferred on textiles.

Whichever print methodology wins the most rounds takes house the championship belt. And remember kids, nobody is getting punched in the head. DTG designs have a shiny look and feel that add vibrancy to the complex designs that DTG is capable of producing. If you spend money on a less expensive DTG printer that goes for round $5,000, you’re sacrificing lots of manufacturing velocity.

Cotton sublimation is feasible with use of additional sublimation sprays and transfer powders, which could be a complex course of. The designer on the print shop will be ready to evaluate your design and assist you to decide on the most suitable choice.

Starting your personal trend line is a giant deal, and as t-shirts are so popular, it makes sense to have them as a half of your line. One of essentially the most important decisions that you must make – after deciding the minimize and magnificence, of course – is the printing methodology that you simply need to go together with.

A DTG machine is basically a large inkjet printer, similar to what you might need at your home or workplace, however it’s designed to print on T-shirts and other clothes. When printing DTG, we call it “full color” but we’re truly using four colours . It works utilizing process printing; achievementlearn.com/ the four colours of CMYK mixing to create a spectrum of colours. DTG depends on course of printing, or the CMYK color model to make numerous shades. While the colours themselves are shiny, they’re also semi-transparent to permit them to be blended more simply. Fluorescents and other vibrant colors outdoors of the CMYK color gamut are potential utilizing plastisol screen-printing inks.

Every time you leave your printer idle for a few days you risk ruining a £1800 printhead. Ideally you'll buy a pretreatment machine and a decent dryer, costing you much more cash.